Metallography of Thermal Spray Coatings

Effects of Different Grinding and Polishing Preparation Techniques

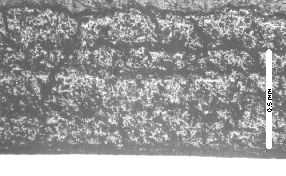

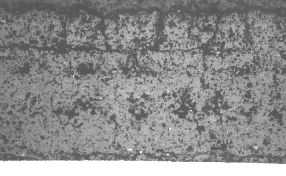

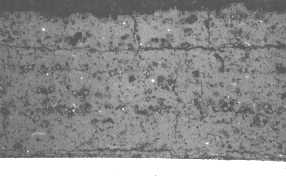

Photomicrographs of the same poorly plasma sprayed alumina / 3% titania coating at about X50 magnifgication. This coating was poorly sprayed by depositing the coating too thickly per pass generating lamination faults. The metallographic preparation precedure for each was slightly different. The two photomicrographs on the left were prepared using fairly typical metallographic techniques for ferrous materials, showing the effects of "particle pluck out". The photomicrograph on the right was prepared using special developed techniques specifically for plasma sprayed alumina ceramic coatings, showing clearly the crack edges, unmelted particles and a more realistic view of density.

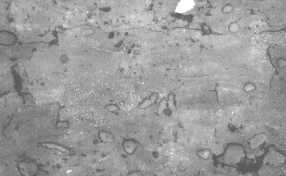

Photomicrographs of the same plasma sprayed alumina/3%

titania coating at about X250 magnifgication.

Alternative Site Recommended for Users of Netscape Navigator and Browsers Not Displaying this Page Properly