Iron

| Element | Iron |

| Symbol | Fe |

| Atomic Number | 26 |

| Molar Mass | 55.85 gmol-1 |

| Electron Configuration | [Ar]3d64s2 |

| Normal State | solid metal |

| Density @STP | 7.87 g cm-3 |

| Melting Point | 1538oC |

| Boiling Point | 2861oC |

| Stable Isotopes | 54Fe, 56Fe, 57Fe, 58Fe |

| Atomic Radius | 124 pm |

| Ionic Radius | 82 (2+) pm |

| Electronegativity (Pauling) | 1.83 |

| Ionization Energy (1st) | 759 kJ mol-1 |

| Ionization Energy (2nd) | 1561 kJ mol-1 |

| Ionization Energy (3rd) | 2957 kJ mol-1 |

| Molar Heat Capacity | 25.1 J K-1mol-1 |

| Standard Molar Entropy | 27.3 J K-1mol-1 |

| Enthalpy of Fusion | 14.9 kJ mol-1 |

| Enthalpy of Vapourization | 351 kJ mol-1 |

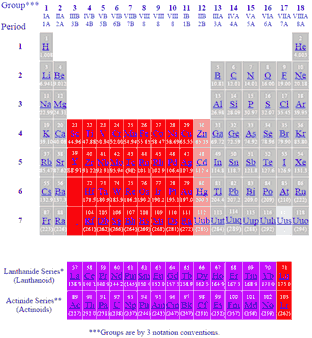

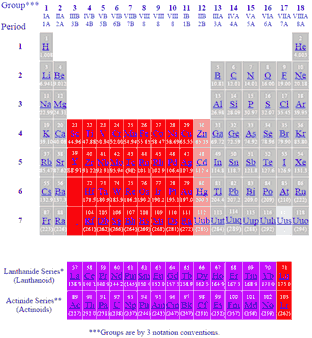

[Back to Periodic table]

- Iron is silver-grey transition metal

- Iron was discovered before 5000 BC

- The "Iron Age" in human history is indicative of the importance of this element

- Native iron in the metallic state occurs rarely as small inclusions in certain basalt rocks and as meteoritic iron

- Iron is the most common element on Earth by mass, forming much of Earth's outer and inner core

- Iron is the fourth most common element in the Earth's crust

- Iron abundance in universe is due to production by fusion in high-mass stars, where it is the last element to be produced

- Iron is reactive to oxygen and water, hence nearly all iron in the earth's crust is in the combined form as oxide ores

- Iron forms compounds mainly in the +2 and +3 oxidation states. Traditionally, iron(II) compounds are called ferrous, and iron(III) compounds ferric

- Iron represents an example of allotropy in a metal. At least four allotropic forms of iron are known

- At 770 °C (the Curie point) iron's magnetic ordering changes from paramagnetic to ferromagnetic

- Pure iron is a relatively soft metal, impurities like carbon have a dramatic effect in increasing hardness and strength

- Crude iron metal is produced in blast furnaces, where ore is reduced by coke to pig iron, which is high carbon and other impurities

- Pig iron is refined further to form cast iron, wrought iron and steel

- Iron is the most widely used of all the metals, accounting for over 90% of worldwide metal production

- Iron's low cost and high strength make it indispensable in engineering applications like machinery, tools and structural components

- Iron is used in a vast range of alloys with a vast range of properties from soft and ductile to super strong and hard to corrosion and heat resistant

- The dominant use of iron is in metallurgy, but iron compounds are also very important chemicals

- Iron is required for life

- Iron plays an important role in biology, forming complexes with oxygen in hemoglobin and myoglobin allowing oxygen transport in the blood of animals

- Iron is a critical element in the metabolism of hundreds of proteins and enzymes involved in diverse body functions, such as oxygen transport, DNA synthesis, and cell growth

Telephone: +44 (0)1252 405186

Email: tsc@gordonengland.co.uk

Site Links

Introducing

Nature of Thermal Spray Coatings

Surface Engineering in a Nutshell

Surface Engineering Forum

Thermal Spray Gun Repair Service

Plasma Consumable Parts

Thermal Spray Powder Supplies

Applications:

Thermal Spray Coatings on Carbon and Glass Fibre Reinforced Polymers

HVOF Coating of Paper Making Roll

Abradable Coatings

Photomicrographs

Thermal Spray Processes:

Combustion Wire Thermal Spray Process

Combustion Powder Thermal Spray Process

Arc Wire Thermal Spray Process

Plasma Thermal Spray Process

HVOF Thermal Spray Process

HVAF Thermal Spray Process

Detonation Thermal Spray Process

Plasma Flame Theory

Cold Spray Coating Process

Wear and Use of Thermal Spray Coatings

Corrosion and Use of Thermal Spray Coatings

Glossary of Thermal Spray and Surface Engineering Terms

Image Directory for Thermal Spray Coatings

Plasma Gas Flow Information

Plasma Gas Flow Correction Calculator

Contact Form

Links to other interesting sites related to thermal spray and surface engineering

Reciprocal Links

Periodic Table of the Elements

SI Units

Calculators for Conversion between Units of Measurement

Hardness Testing

Surface Engineering Message Board Archive

Surface Engineering Message Board Archive Index

Photography Gallery2

Photography Gallery3

© Copyright Gordon England