Chromium

| Element | Chromium |

| Symbol | Cr |

| Atomic Number | 24 |

| Molar Mass | 52 gmol-1 |

| Electron Configuration | [Ar]3d54s1 |

| Normal State | solid metal |

| Density @STP | 7.19 g cm-3 |

| Melting Point | 1907oC |

| Boiling Point | 2671oC |

| Stable Isotopes | 50Cr, 52Cr, 53Cr, 54Cr |

| Atomic Radius | 129 pm |

| Ionic Radius | 84 (2+) pm |

| Electronegativity (Pauling) | 1.66 |

| Ionization Energy (1st) | 653 kJ mol-1 |

| Ionization Energy (2nd) | 1492 kJ mol-1 |

| Ionization Energy (3rd) | 2987 kJ mol-1 |

| Molar Heat Capacity | 23.4 J K-1mol-1 |

| Standard Molar Entropy | 23.8 J K-1mol-1 |

| Enthalpy of Fusion | 15.3 kJ mol-1 |

| Enthalpy of Vapourization | 348.78 kJ mol-1 |

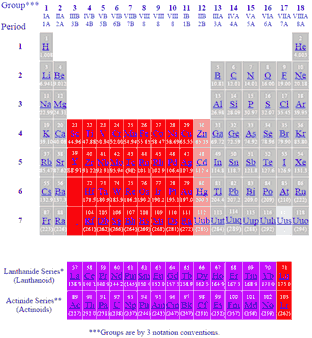

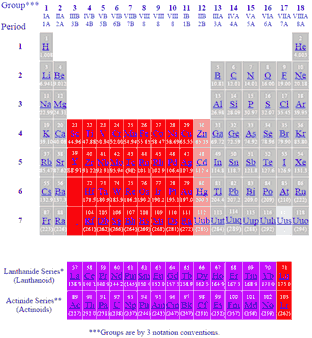

[Back to Periodic table]

- Chromium is a hard silvery metallic transition metal element

- Chromium discovered by Louis Nicolas Vauquelin (1794) and first isolation (1797)

- Chromium is the only elemental solid showing antiferromagnetic ordering at and below room temperature, above 38 °C it changes to paramagnetic

- Chromium is passivated by oxidation readily in air forming a thin, protective, surface layer leading to excellent anti-corrosion properties

- Chromium is the 22nd most abundant element in Earth's crust

- Although rare, deposits of native chromium exist

- Chromium is mined as chromite (FeCr2O4) ore

- Chromium has a wide range of oxidation states, with +3 the most stable, +3 and +6 are the most common, while +1, +4 and +5 are less common.

- Metal alloys account for 85% of the use of chromium. The remainder is used in the chemical, refractory, and foundry industries

- Pure chromium metal rarely used alone, except as an electoplated deposit (decorative or hard chrome plate)

- Strengthening effect and increase in corrosion resistance made chromium an important alloying material for steel and other metal alloys

- Chromium is an important alloying addition to stainless steel, nickel and cobalt super alloys and many other metal alloys

- Strong oxidative properties of chromates are used to form protective oxide layer on metals like aluminium, zinc and cadmium (chromate conversion coating process)

- Chromium compounds used in dye, pigments, leather tanning, primers, paints, wood preservatives

- Chromium gives colour to rubies and saphire gem stones, synthetic ruby crystal was used for the first laser (1960) relying on emission of light from the chromium atoms

- Chromium forms important refracory materials

- Chromium(IV) oxide is used to manufacture magnetic tape used in high-performance audio tape and standard audio cassettes

- Chromium(III) oxide (Cr2O3) is a metal polish known as green rouge

- Chromium(III) oxide (Cr2O3) is thermal sprayed to produce extremely hard protective coatings on many substrates

- Chrome alum is Chromium(III) potassium sulfate and is used as a mordant (a fixing agent) for dyes in fabric and in tanning

- Trivalent chromium, Cr(III), or Cr3+ is an essential nutrient as a trace element

- Hexalent chromium, Cr(VI), or Cr6+ is highly toxic and mutagenic

Telephone: +44 (0)1252 405186

Email: tsc@gordonengland.co.uk

Site Links

Introducing

Nature of Thermal Spray Coatings

Surface Engineering in a Nutshell

Surface Engineering Forum

Thermal Spray Gun Repair Service

Plasma Consumable Parts

Thermal Spray Powder Supplies

Applications:

Thermal Spray Coatings on Carbon and Glass Fibre Reinforced Polymers

HVOF Coating of Paper Making Roll

Abradable Coatings

Photomicrographs

Thermal Spray Processes:

Combustion Wire Thermal Spray Process

Combustion Powder Thermal Spray Process

Arc Wire Thermal Spray Process

Plasma Thermal Spray Process

HVOF Thermal Spray Process

HVAF Thermal Spray Process

Detonation Thermal Spray Process

Plasma Flame Theory

Cold Spray Coating Process

Wear and Use of Thermal Spray Coatings

Corrosion and Use of Thermal Spray Coatings

Glossary of Thermal Spray and Surface Engineering Terms

Image Directory for Thermal Spray Coatings

Plasma Gas Flow Information

Plasma Gas Flow Correction Calculator

Contact Form

Links to other interesting sites related to thermal spray and surface engineering

Reciprocal Links

Periodic Table of the Elements

SI Units

Calculators for Conversion between Units of Measurement

Hardness Testing

Surface Engineering Message Board Archive

Surface Engineering Message Board Archive Index

Photography Gallery2

Photography Gallery3

© Copyright Gordon England