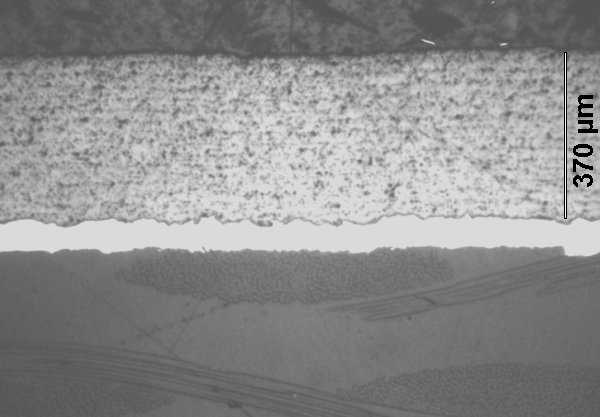

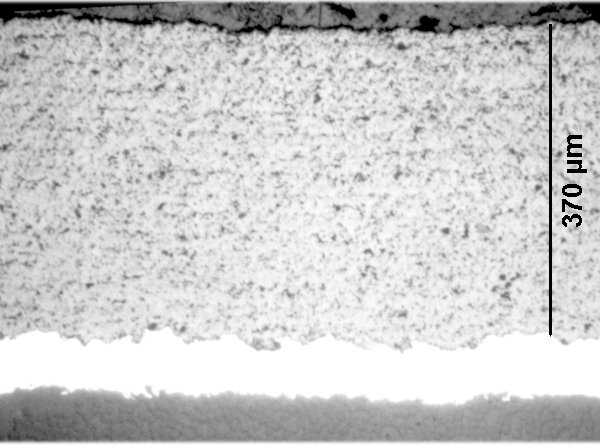

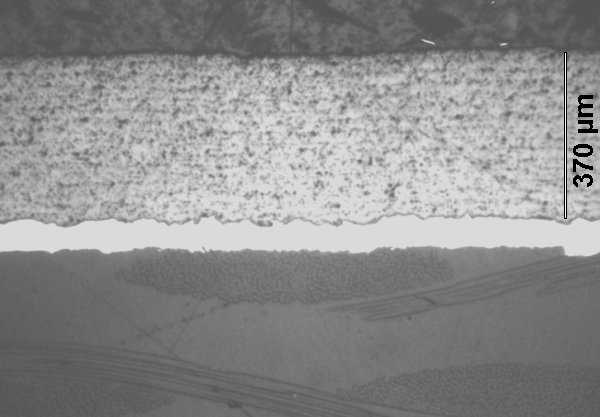

Carbon fibre reinforced polymer tubes thermal spray coated with:

Top left - WC/10Co/4CrTop right - NiCrBSi

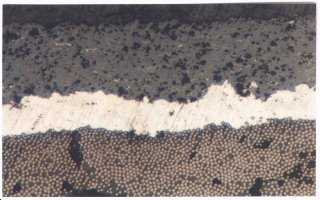

Bottom left - Chromium oxide

Bottom right - Alumina /3% titania

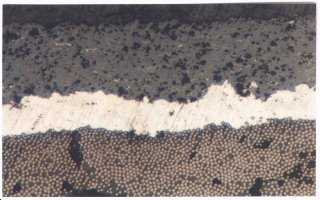

Glass fibre reinforced polymer plasma sprayed with chromium oxide

Some applications using thermal spray coatings on heat sensitive substrates like plastics, wood, paper and other non metal parts

are used today. Most of these coatings are based on zinc and aluminium,

which are mainly used for R.F.I. shielding and electrical conductivity

where mechanical properties of the coating are not of prime importance.

The use of reinforced plastics is an attractive option over metals

in some components because of the good strength to weight ratio. The

disadvantage is the poor surface properties.

Applications that need thermal spray coatings with good mechanical

properties for resistance to wear for example are few, because of the

difficulty in getting adequate bond strength between plastic substrate

and coating.

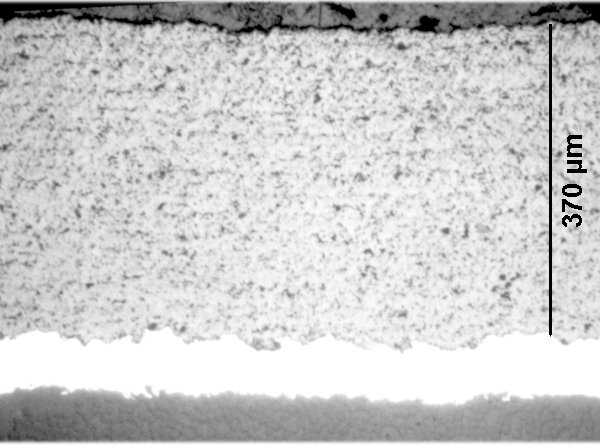

Recent development work has indicated promise for engineering type

thermal spray coatings on fibre reinforced polymers. Careful selection

of material combinations and the use of special process parameters has

produced relatively thick coatings in metals, ceramics and carbides

which can be machined or ground.

If you are considering the use of reinforced polymers, but are put

off because of problems with surface properties or the apparent lack of

surface engineering solutions, please get in contact for advice.