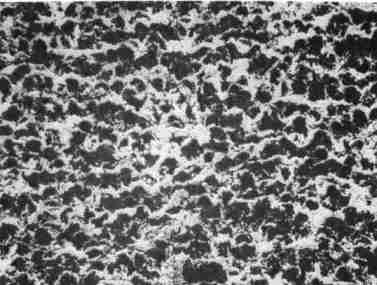

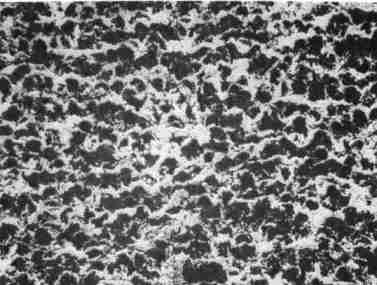

Plasma sprayed Aluminium Silicon Alloy / Polyester Abradable Coating

Abradable coatings are designed to preferentially abrade when contact is made with a mating part. Thermal spray abradable coatings have low structural integrity so they are readily abraded when they come into contact with a moving surface with higher structural integrity. The coatings are designed not to damage the mating surface.

There are a number of different abradable coating types, to cater for different operating temperatures, corrosive environments and mating materials. The coating structure can be either:

Plasma sprayed Aluminium Silicon Alloy / Polyester Abradable Coating

The main application of thermal spray abradable coatings is for gas path clearance control in gas turbine engines. In an ideal situation, gas turbine engines would be manufactured with minimal clearance in the gas seal locations, but in the real world these clearances are very much larger to permit operation without catastrophic interaction between rotor and the casing. The clearance at the gas seal locations has a significant effect on the gas turbine engine efficiency which directly translates to fuel consumption. Thermal spray abradable coatings successfully reduce these clearances to a minimum, without the risk of catastrophic failure.

Schematic of a Typical Gas Turbine Engine

These coatings are used in the original manufacture to provide the best possible seals in the first instance. They are also used during overhaul to repair any excessive clearance produced during service. Substantial improvement in engine performance and efficiency can be realised by operating with clearances smaller than those achieved in the original manufacture where abradable coatings were not used.

This technology is now spreading to other applications, such as land based turbines and rotor seals in turbochargers for internal combustion engines.

Thermal spray abradable coatings commonly used in order of increasing temperature capability:

Introducing

Nature of Thermal Spray Coatings

Surface Engineering in a Nutshell

Surface Engineering Forum

Thermal Spray Gun Repair Service

Plasma Consumable Parts

Thermal Spray Powder Supplies

Applications:

Thermal Spray Coatings on Carbon and Glass Fibre Reinforced Polymers

HVOF Coating of Paper Making Roll

Abradable Coatings

Thermal Spray Processes:

Combustion Wire Thermal Spray Process

Combustion Powder Thermal Spray Process

Arc Wire Thermal Spray Process

Plasma Thermal Spray Process

HVOF Thermal Spray Process

HVAF Thermal Spray Process

Detonation Thermal Spray Process

Plasma Flame Theory

Cold Spray Coating Process

Wear and Use of Thermal Spray Coatings

Corrosion and Use of Thermal Spray Coatings

Glossary of Thermal Spray and Surface Engineering Terms

Image Directory for Thermal Spray Coatings

Plasma Gas Flow Information

Plasma Gas Flow Correction Calculator

Contact Form

Links to other interesting sites related to thermal spray and surface engineering

Reciprocal Links

Periodic Table of the Elements

SI Units

Calculators for Conversion between Units of Measurement

Hardness Testing

Surface Engineering Message Board Archive

Surface Engineering Message Board Archive Index

Photography Gallery

Photography Gallery3

© Copyright Gordon England